By John Roberts*

*The Author’s father, Fred Roberts was the developer of the Kingswear and Dartmouth Golf Course in

1938 and Fred owned a small sawmill close to the River Dart from 1923 to 1935. The ways of working the mill are described here by his son John, including the felling of trees, transport of the wood by boat

to the mill, descriptions of the sawmill and the engine in the mill. John’s account is published exactly as he wrote it in 1955.

Thanks to Harold Hutchins of Dartmouth, who passed on this and several other documents from John.

John Roberts passed away in 2006

John’s father, Fred Roberts’ story is described in “A History of Local Golf and the Kingswear and

Dartmouth Golf Club” by Chris Ryan and also published by the Kingswear Historians.

Produced by Chris Ryan for the Kingswear Historians November 2007

Introduction

The practices of sawmills have changed drastically since the 1923-1935 period when the

authors father owned a sawmill close to the River Dart in Devon. Present day heavy

machinery has reduced the hard physical toil of sawmills. Progress also means that many of

the then products and uses of timber no longer exist. This article looks back at how a

sawmill operated earlier in the 20th Century.

Acquiring the Mill

Following the end of the First World War, my father, who had returned to his home area,

found that the plant used in the building of the extension of Britannia Royal Naval College at

Dartmouth was being sold. This included a saw bench and the engine to drive it, with sundry

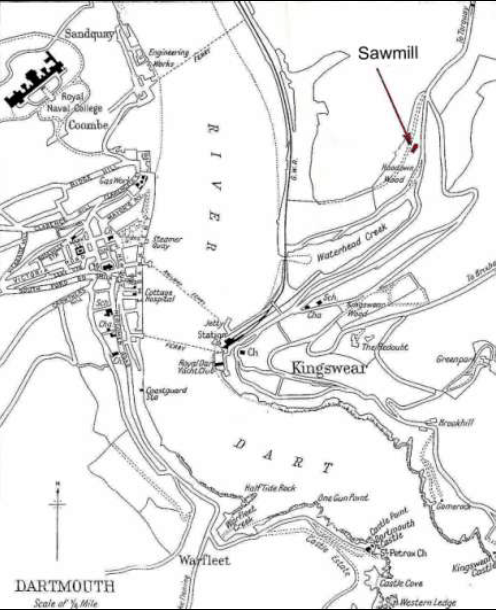

other items. These my father bought. They were transported to the other side of the River

Dart and were set up on my family’s land at Waterhead Creek, Kingswear.

For a while there were sufficient trees in the woods surrounding the sawmill, but soon my

father had to look further afield. He found supplies close to the water’s edge at Old Mill

Creek, Dartmouth and also further up river at Sharpham. The better, mature trees were

found up in the sheltered creeks. The trees which tourists see from the river are mainly

dwarf oaks, once used for charcoal burning.

Felling the Trees

Only single trees were selected for felling, which therefore did not deplete the area or cause

any unsightly gaps in the woods. Great care was taken to minimise any damage to the

surrounding timber as the trees were felled. All the work was done by hand labour and the

rhythmic sound of the cross cuts could almost have been said to be soothing, especially

compared to the present day chainsaw which shatters the peace of the countryside.

The saw my father favoured most was a flexible 1.8 meter long, narrow one, with a 15 cm

blade, which is now in a museum in Welshpool. It had a two handled cross cut, with teeth

set in groups of four, with a small gap between each pair in the four. This gap was said to be

for clearing out the sawdust from the cut. The saw was difficult to use because it was so

flexible. One had to be extremely skilful to hold it correctly when making horizontal cuts into

a standing tree, otherwise it would wander all over the place and cause much hard work. I

know because as a boy, I took one end of the saw on numerous occasions. Dividing the

trunk into sections after it had fallen was much easier work! When lopping off the branches

of, say an oak tree, care was taken to see if there were any 90 or near 90 degree bends, as

from these ‘knees’ or similar pieces could be taken for boat building

Transportation

After felling the timber manually by saw and axe, the logs had to be moved to the edge of

the water by levers on wooded rollers.

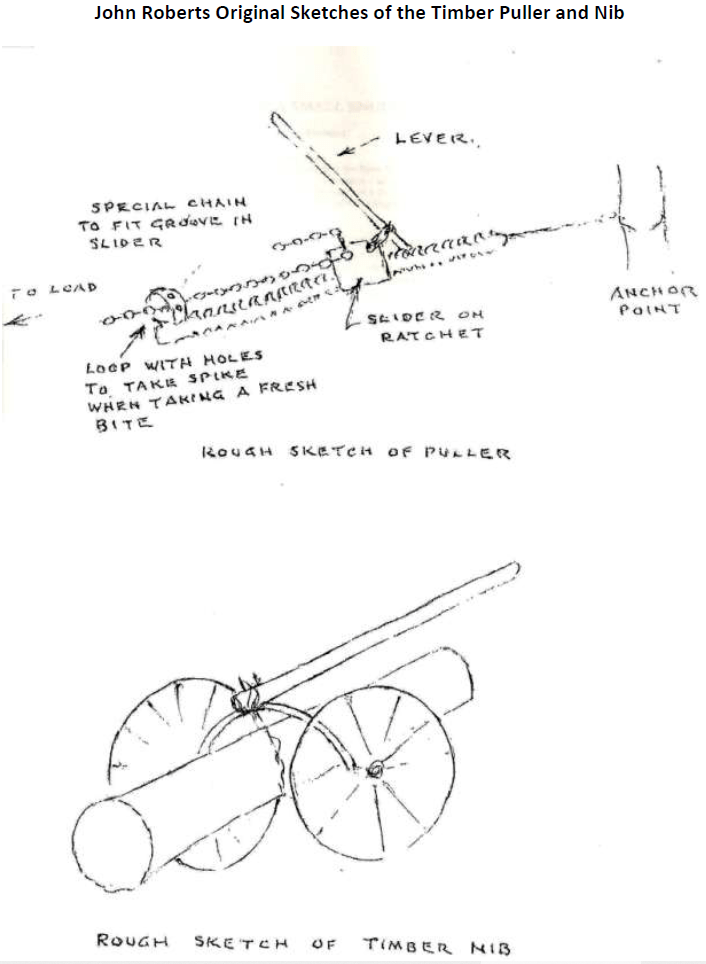

When the trunks were very heavy, or in a difficult position, we had to use a ‘pit prop puller’

which was very efficient. It consisted of a metal bar with teeth or slots on both sides, which

ran a ratchet device, operated by a long lever. One end was anchored by a chain to a nearby

tree – the other to the log which could then be moved a few feet at a time.

Even though the trees were felled, when the sap was at very low levels, they were often left

for a few months to dry out and they were eventually transported to the saw mill by water.

This was done by motor boat, with an older boat in tow, to which non floating logs could be

supported in a ‘pannier’ position each side. Lighter weight, softwood ‘floaters’ could be

towed on their own.

Tides had to be chosen carefully because of the nature of the Dart Estuary. We loaded at

high water, ran downstream with the current and finished up with enough water to enter

Waterhead Creek where the mill was located. After reaching the hard standing at the end of

the creek, the logs had to be conveyed up to the mill – some 300 yards distant.

A timber ‘nib’ was used to lift the logs. This consisted of a pair of large diameter iron wheels

connected to a metal axle in the shape of a horseshoe, with a timber beam at its central

point. The beam was lifted up and the centre of the horseshoe was lowered onto the log

and secured. The beam was brought down to the back of a cart and pulled up by horse to

the sawmill.

One day, the road was slippery and the horse fell, turning over the cart, but fortunately a

sack was available to cover the horse’s head to stop it from struggling. The horse was freed

before any damage was done.

Saw and Bench Engine

The bench was some 9 meters long with rollers every 60cm to take a travelling table which

carried the log to be cut. The table was fitted with a metal rack which was operated by a

single crank handle. The circular saw, some 1 meter in diameter, was set over a pit to catch

the sawdust. The belt was driven by a fast and loose pulley.

The engine was a large 25 horse power single cylinder Ruston Homsby with a 1.5 meter

diameter flywheel and a smaller drive pulley. It was started by heating a bulb with a large

vertical blowlamp to red heat. This vaporised the fuel and the engine was made to fire by

pulling on the flywheel or belt – getting ready to let go immediately should it backfire! The

engine, to my ears at least, made a lovely sound “chuff chuff, chuff-bang” when idling – or

chuff-bang chuff-bang when on light load. But bang, bang, BANG, BANG on full load. The

latter sound was far less pleasant!

The logs to be sawn were loaded onto the table by crane. The roof above was raised on a

hinged flap to give clearance for the wire cable

Training

In those days there was a lack of adequate training for the men employed in the timber

industry. My father – the third son of a farmer – learned his trade apprenticed to a large

ship building firm on the River Dart. This was in the late 1890’s when the bosses took little

interest in the boy’s training – leaving this to the older men. These gave little help beyond

setting them to work on menial tasks, such as smoothing rough castings, or filing away for

hours on bronze propellers to achieve a good balance. There was little chance of getting

practice on a lathe, as the older men were possessive of their jobs and afraid that once

skilled, the younger boys would oust them from their jobs. Today, schoolboys – and even

schoolgirls, have access to excellent modern lathes and other woodworking equipment.

Timbers Processed and their Uses

There has been much change as to the uses to which such timber is now put. In those days

all sorts of timber was sawn: oak, chestnut, elm, larch, fir, sycamore – and once even

greenheart. The latter was cut when a disused jetty was dismantled and a few piles

acquired. This wood was extremely hard and made excellent fence posts, but it really

punished the saw by getting it too hot. Large oak logs did the same, causing the saw to

overheat and become distorted – and making a dreadful noise. A coating of old engine oil

applied with a brush while the saw was running helped to cool it.

Oak and chestnut were in demand for fencing, gates and gate posts. When rough sawn it

was difficult to differentiate between these woods and many who came along to choose

their own timber, went off with the wrong kind!

Elm (no disease in those days) was mainly used for coffin boards. It was useless for fencing

posts, rotting off at ground level in as little as four years. Strangely enough it was often used

for boatbuilding as it was not affected by salt water.

Ash, being elastic, was used for carriage and wagon shafts and bodywork. Also, because it

could be easily bent, it was also used for boatbuilding e.g. for ribs and top strakes in rowing

boats. Any surplus made excellent firewood!

Larch was used for standard field gates, but there was little call for timber such as beech,

because the furniture industry was too far away. Neither was there demand for local home

grown timber for the building trade, as all softwoods were imported by ship and unloaded

upstream at Totnes. The subsequent loss of timber importation up the Dart occurred

because of the increase in the size of ships and the shallowness of the upper reaches of the

River Dart. During this period the troopships from Dorset and Somerset were laid up in

Dartmouth Harbour during the summer months.

My father was contracted to supply them with some rough timber and this developed

further – so that when a better class of timber was needed, my father acted as agent for a

local timber merchant. In one case, a long awning spar broke during a storm and had to be

replaced. It was 6 meters long with a rounded top. As only the best was acceptable, we

secured a most beautiful piece of Norway Spruce – straight grained, clean and free from

knots.

Then loss of some uses of timber could be said to be a negative consequence of progress.

The change from smaller manually based enterprises to today’s machinery is a much more a

positive move forward with the activities of each sawmill worked out by computer and the

hard work all dome by machine. How the old artisans would have marvelled at the use of

steel tubing and fastenings!

John Roberts

Brynawelon, Groespluen, Welshpool, Powys SY21 9BW